Salt

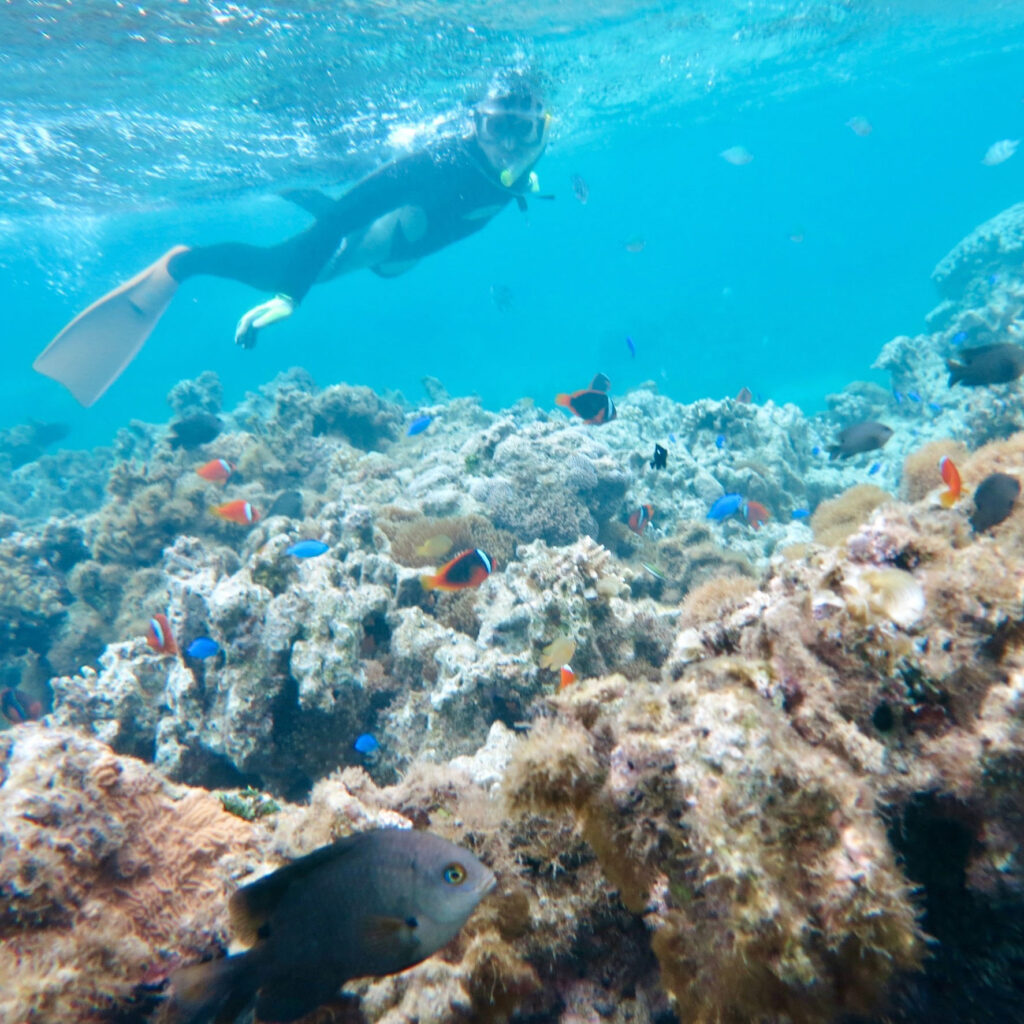

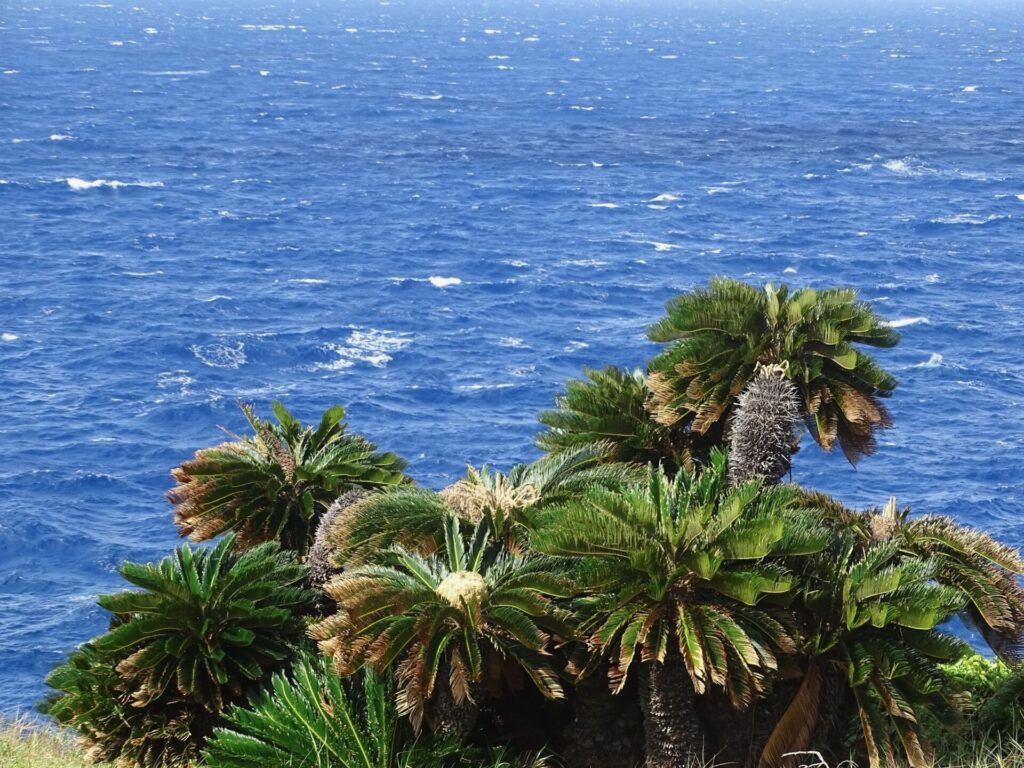

The reason why salt is called māsu in the Okinawan language is apparently that it is derived from mashio1 in Japanese. Salt is essential to life, and since Okinawa is surrounded by the sea, salt has been produced for a long time. One method of making salt was to boil seawater in a pot, but this process consumed large quantities of fuel and was inefficient. With so much strong sunlight readily available, the wiser method was to use this sunlight to raise the salt concentration of the ocean water to turn it into a brine before boiling. In fact, this method was used in every part of the Ryukyus. Until the beginning of the Taisho Era (1912-1926), every village had a salt beach or fields. Instead of the salt fields, there was also the method of using coral reef cavities to produce salt, a method that is very “Okinawan.”

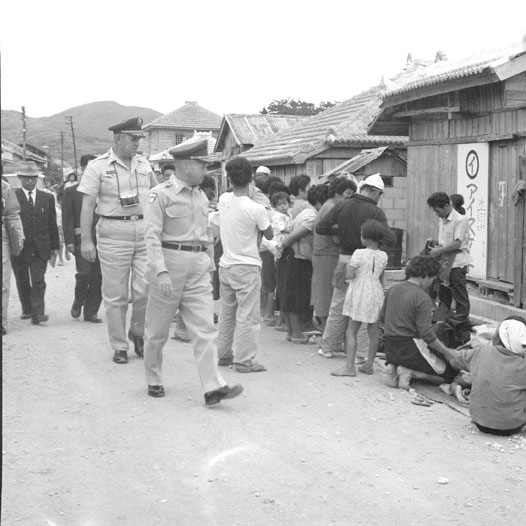

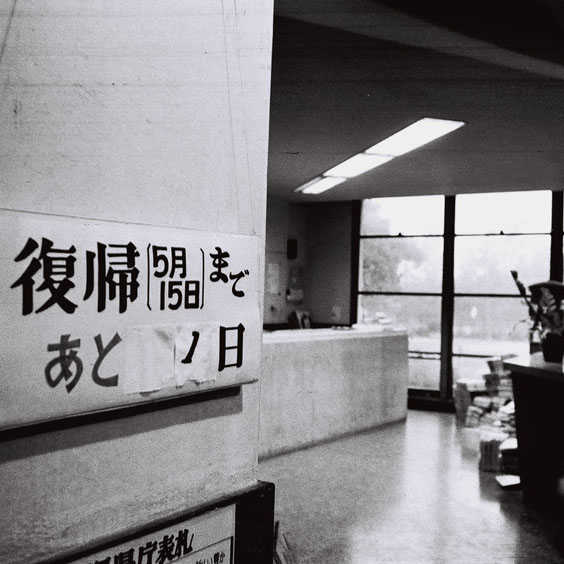

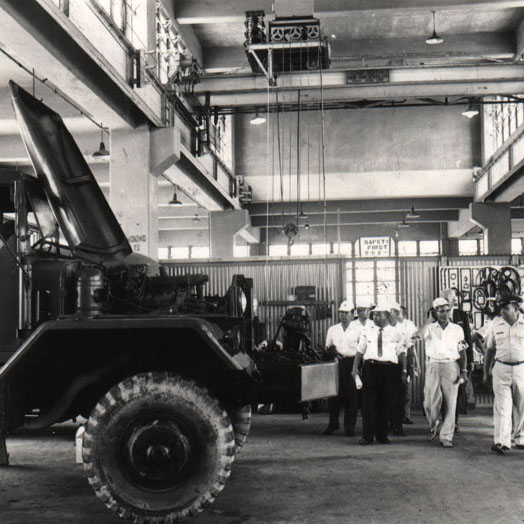

Until the postwar Reversion, there was a company called Okinawa Seien (Okinawa Salt Co.) in Misato Awase (now, Okinawa City), where salt was manufactured using modern methods in the salt fields. However, the company was closed after the Reversion.

Then on, salt was produced under a Japanese monopoly, but the company (now, Japan Tobacco) abandoned the salt field method and enforced the ion exchange process instead. The result was so unpalatable that the ban on natural salt was recently lifted. There are now several companies even within Okinawa that are manufacturing salt using their own methods. There are some companies where rock salt is dissolved and allowed to recrystallize. However, here, I would like to introduce what is considered the superior Aguni salt of Aguni Island.

Aguni salt is made using a special technique. First, cement blocks with holes are piled, and a fence about 10 meters high is built around it to keep the wind out. Inside, numerous bamboo poles are hung upside down and seawater is pumped up from the ocean to be poured over the branches. The seawater dribbles down the bamboo from branch to branch. In the space between the branches, moisture evaporates and raises the salt concentration. Repeating this process over and over again results in a concentration of salt which is six times higher by the fourth day.

Next, there are two different procedures. The first is to pour the concentrated seawater into a shallow, flat iron pan and bring it to a slow boil using firewood. The other choice is to put the liquid in a shallow trough inside a greenhouse and evaporate it using only sunlight. Regardless of whichever method is used, the salt is crystallized in the end and gathered into containers with a bamboo mesh bottom through which the little remaining moisture drains out and the salt completely dries.

The high ion content in the Aguni salt is what makes it superior compared to other salts. Salt made through the ion exchange method only contains sodium chloride, and discarding the other ions in natural seawater is bad news for our health. Fifteen percent of Aguni salt is composed of ions besides sodium chloride, and this number is the best in the world.

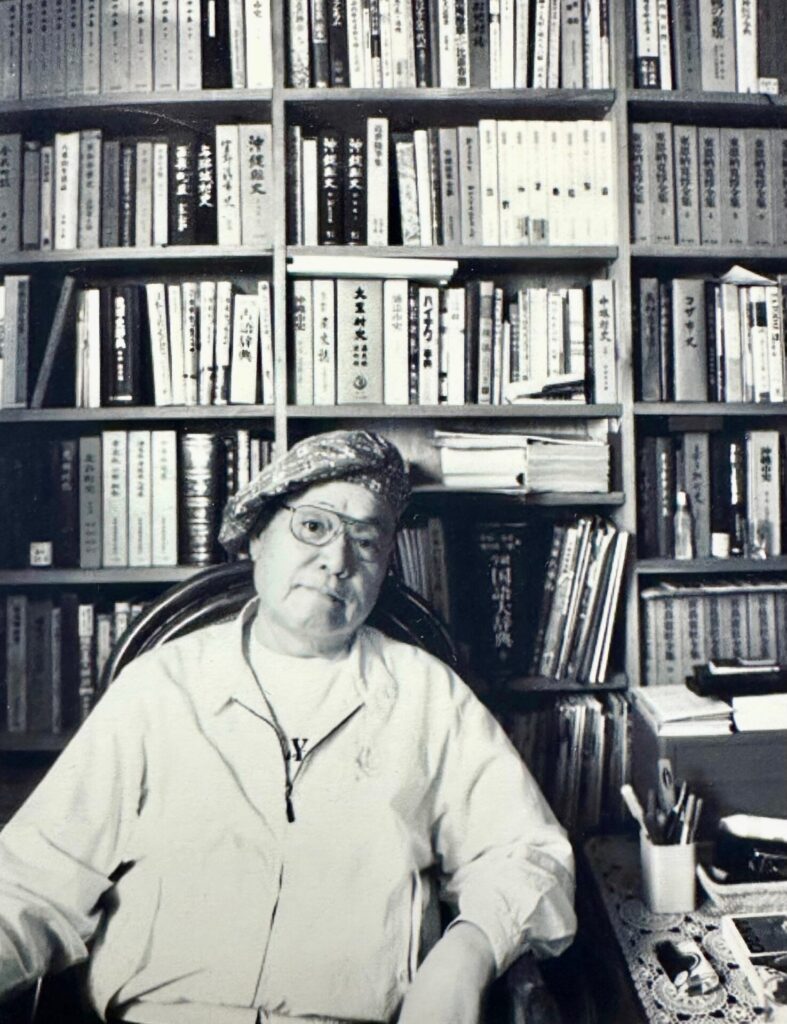

A further point worth mentioning is that the Aguni Island salt industry actually benefited from the issues of the island’s shrinking population and lack of farms. With very few people and minimal agriculture, seawater is untainted with waste and pesticides. The island is small and the concentration of salt is high in its surrounding sea due to the strong winds. Odo Koshin, a developer, says that if Aguni salt encompassed just 1% of Japan‘s salt consumption, the island would be able to live off of that. Since there is very little to export outside Okinawa, this one person’s untiring research over a long period of time to transform salt into a popular commodity is truly worthy of praise.

Editor’s Note:

- A type of high quality salt.