Indigo

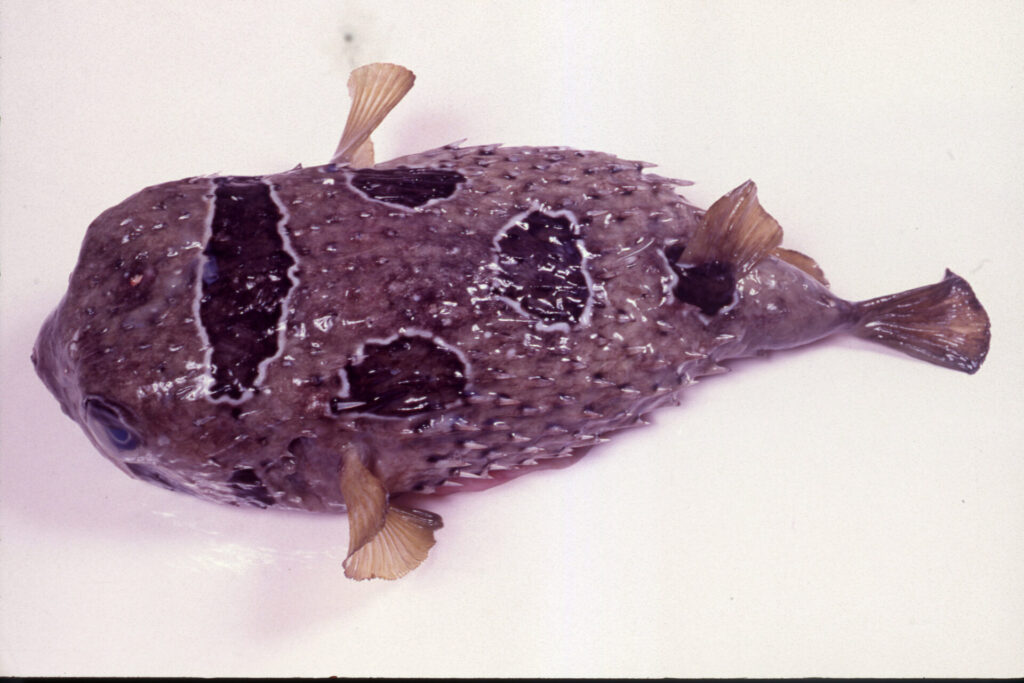

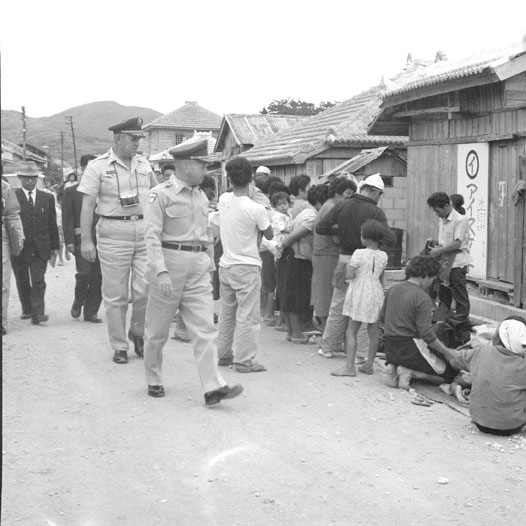

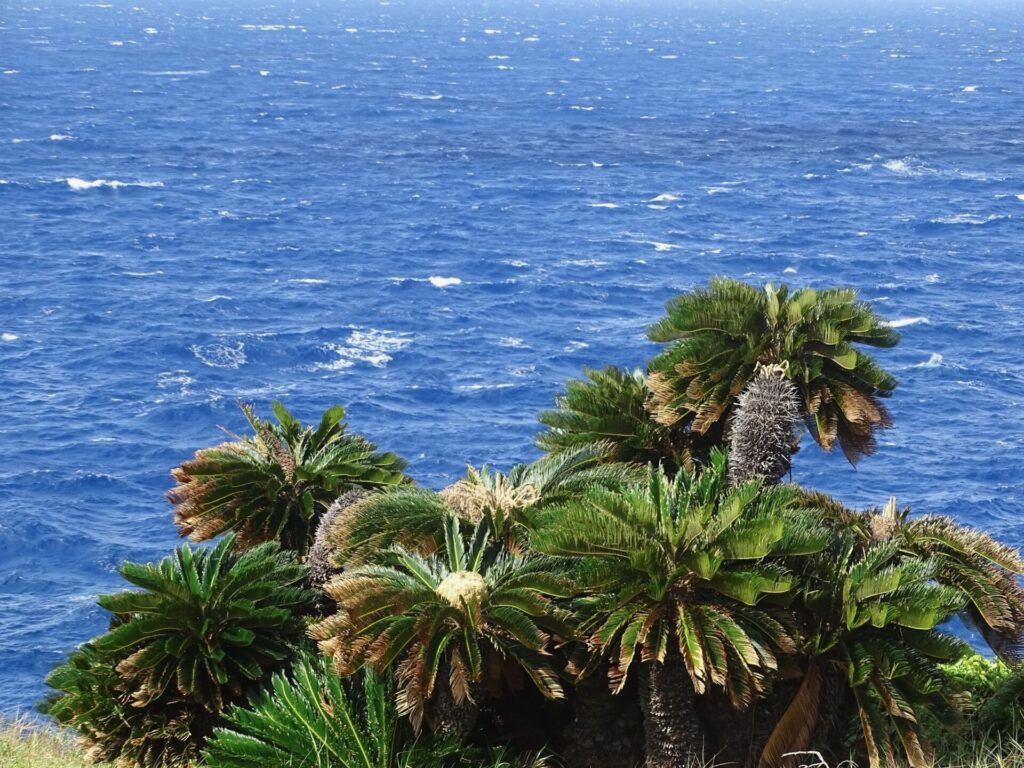

Photo: TARUMI Kengo

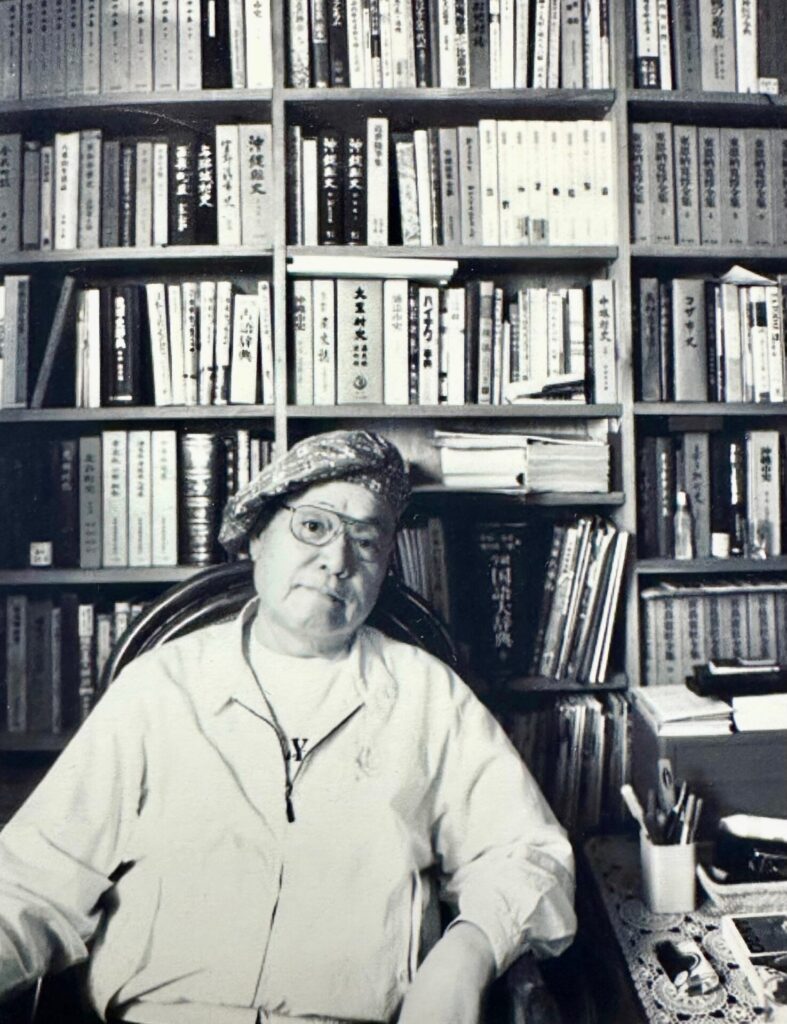

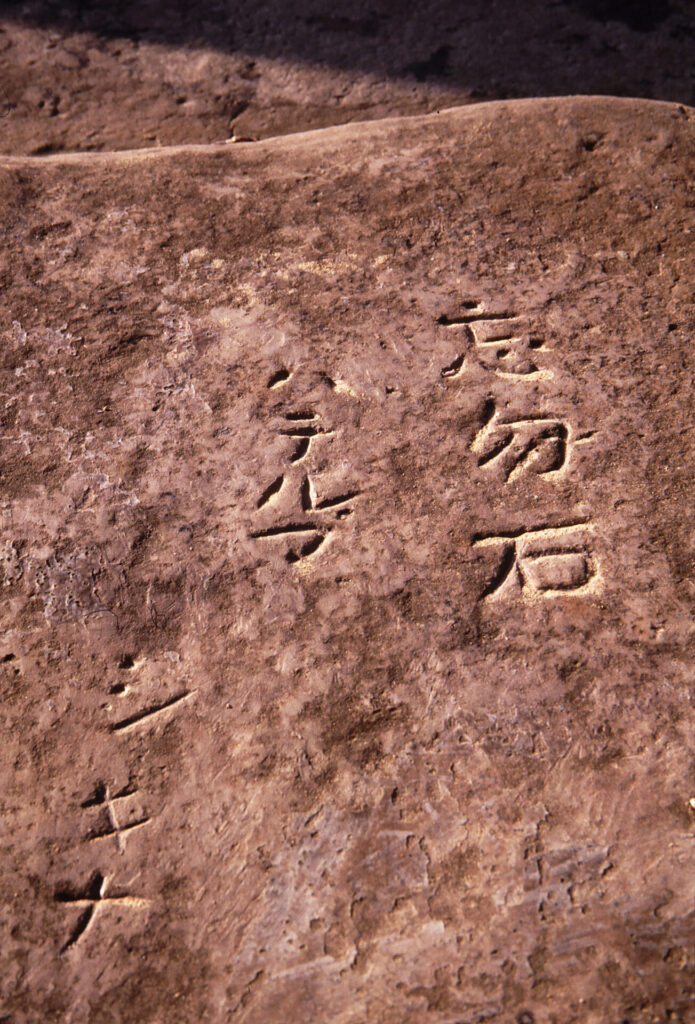

At the time of this writing (1998), it’ll be twenty years since I first started living in the middle of nowhere deep in the mountains of the Yanbaru region (near Ōshittai and Genka in Nago City.) It is in the water-rich greens deep in these mountains that I first encountered one of the priceless, precious things I am determined to pass on to the next generation, a sign of “true wealth.”

The Assam indigo.

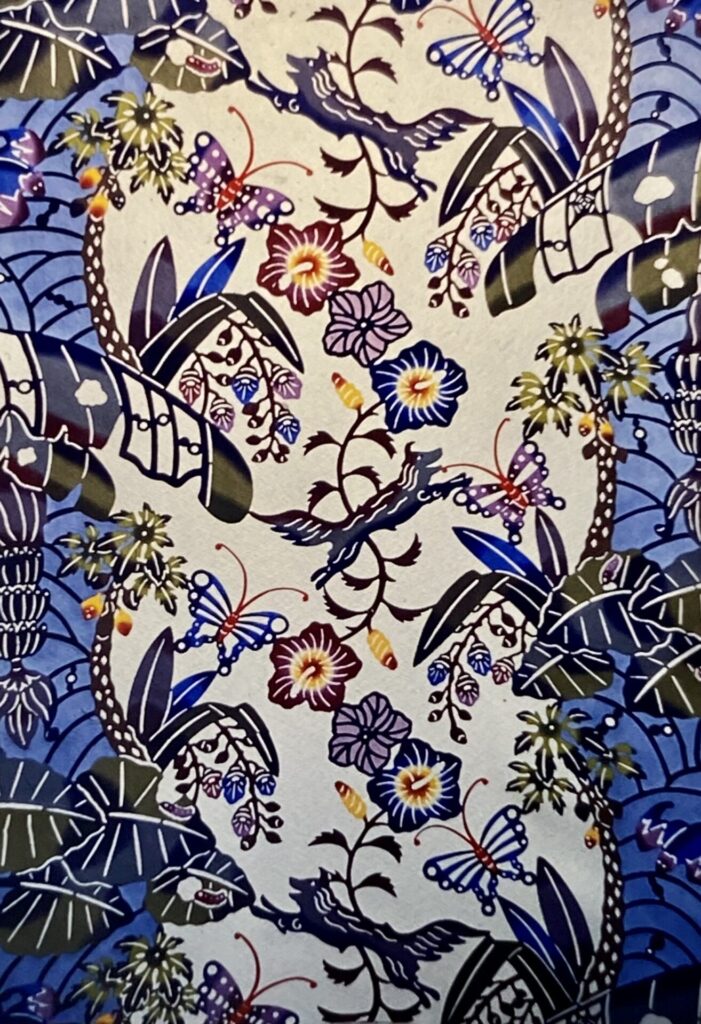

Three different varieties of indigo grow in Okinawa. One variety is the same as that found on Yonaguni Island, a variety in the knotweed family, and is used in the making of Miyako jōfu fabric. Another is actually in the pea family—though it’s called anil indigo—and it’s used on Taketomi Island. And then there’s the one I encountered—Assam indigo (in the Acanthaceae family). The most beautiful indigo dye in the world, used in making Ryukyu kasuri and the blues found in bingata stencil dyeing, all come from the Assam indigo. Even today, it’s often used to produce Miyako jōfu, Yaeyama jōfu, and other woven products made on Okinawa’s big island as well as the outlying islands, and you must not miss out on Okinawa’s traditional forms of dyeing and weaving. The high quality of our indigo is praised worldwide, because it produces a depth of color and a clarity not found in other indigo varieties. One of its wonderful qualities is that the deeper the indigo dye becomes, the more red appears in the end product, until eventually dyed fabrics give off a purple glow. Moreover, another charm of the Assam indigo plant is that instead of harsher chemicals, one needs only vinegar to stop the dyeing process and naturally fix the color. I don’t think it would be exaggerating to call this the pinnacle of natural dyeing processes.

Assam indigo likes wild, damp, green places more than leveled fields, which means it prefers mountains or wetlands where it can be in partial shade. Okinawa’s sultry subtropical climate in the Yanbaru region of the northern main island where trees and shrubs are abundant is the perfect place to propagate and harvest good quality indigo, used in the making of “muddy indigo.” Okinawa now accounts for more than ninety percent of the Assam indigo supply.

Muddy indigo is made from the harvested indigo leaf, and is a result of the coordination of Yanbaru’s magnificent natural world and the skilled dyers who take the indigo through a fermentation process to produce the final dye; Yanbaru and the dyers continue to survive and support each other.

Long ago (before the war), it was quite common for families to plant indigo in the shade made by houses or the trees at the edges of fields, ferment the leaves, and make their own dyed clothing. Yanbaru also flourished as a dedicated indigo production site, so much so that “muddy indigo” became one of its most profitable exports, second only to brown sugar.

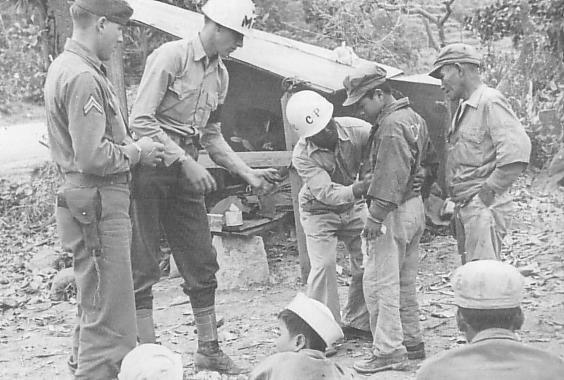

After the war, the adoption of synthetic chemical dyes, the increasing demand for muddy indigo, and several other factors all contributed to the gradual disappearance of those who lived and breathed through indigo production. The traditional methods of muddy indigo making, which had passed from parent to child, disappeared along with them.

Now, those who carry on the making of muddy indigo are glancingly few (you can find them in Nago in Motobu on the northern part of main island). They are now also facing the dangerous destruction of Yanbaru’s wonderful natural world, which is threatened in the name of regional development.

In this day and age, you can only find the “real deal” in the so-called hinterland or those places that have been spared development, and we must not turn our backs on these places by making regional improvement plans that sacrifice the environment just to cut costs. I believe it is my calling to ensure that real Assam indigo and the magnificent Yanbaru ecosystem that gave birth to it are passed on to the next generation.