Miyako Jōfu

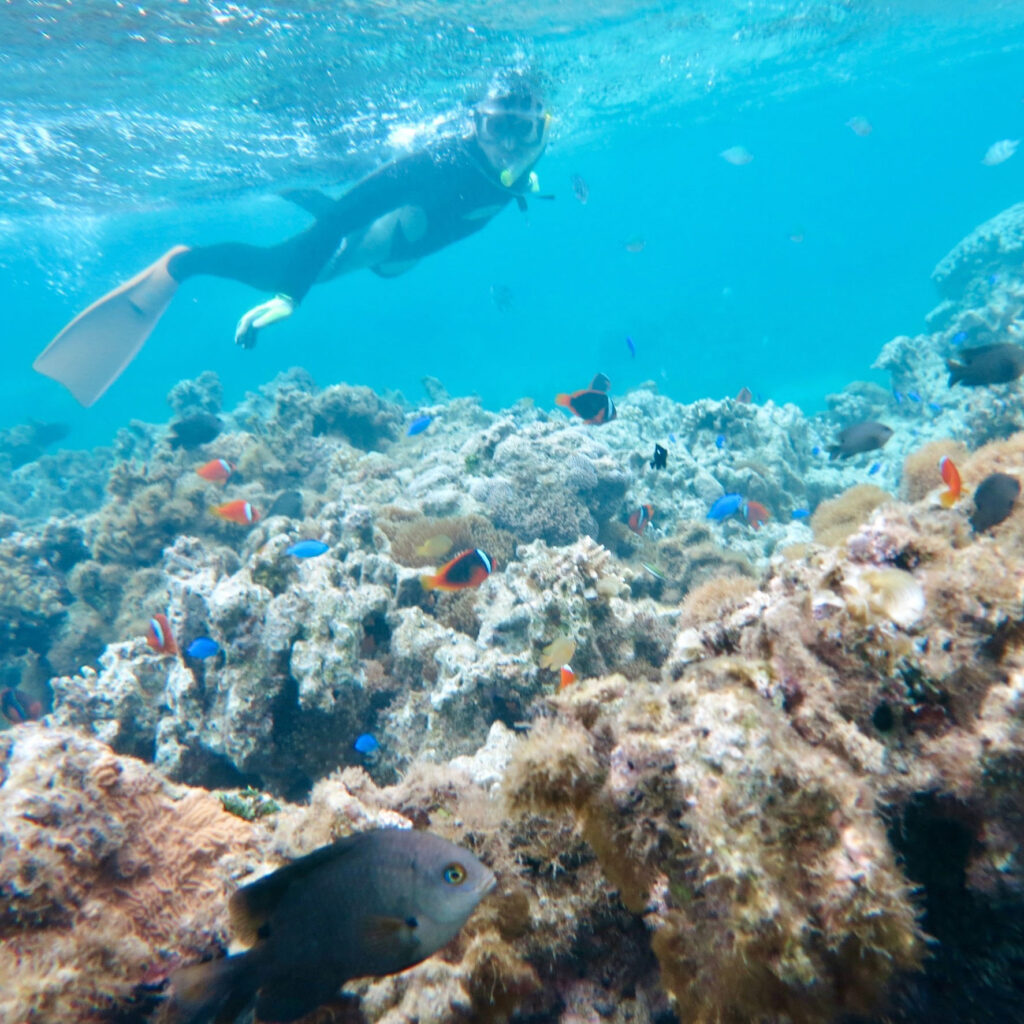

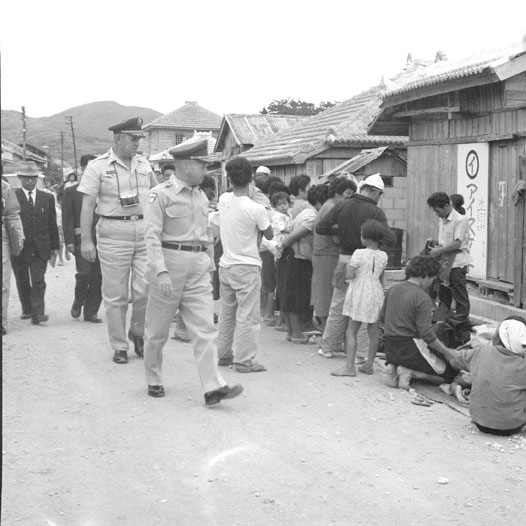

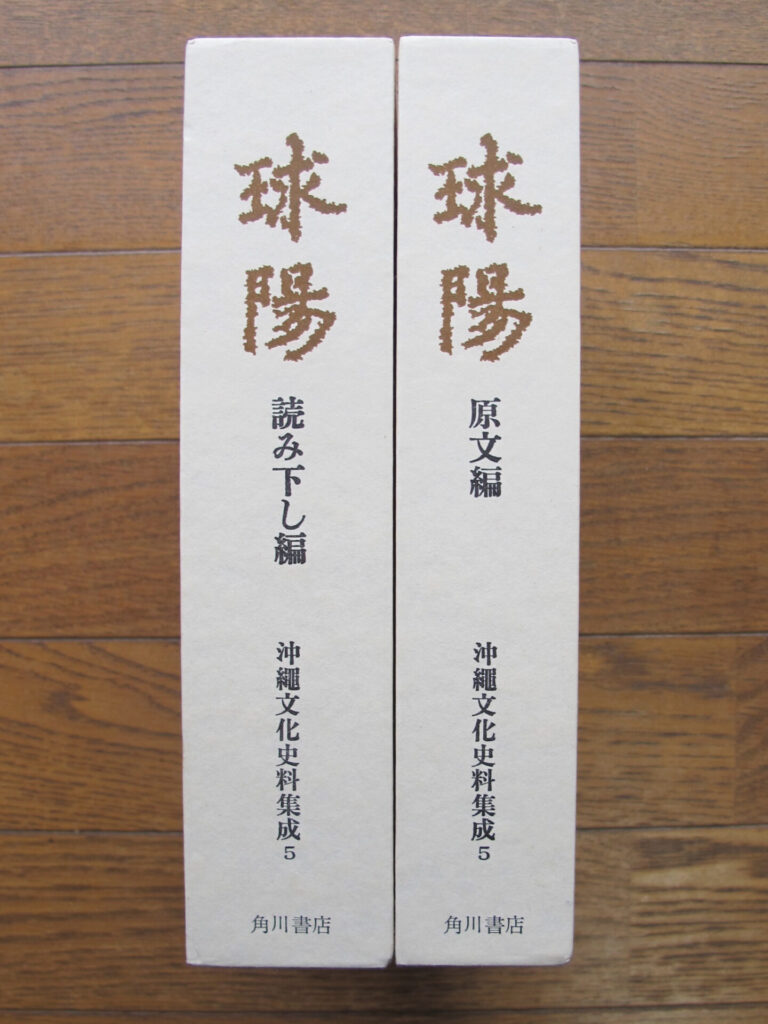

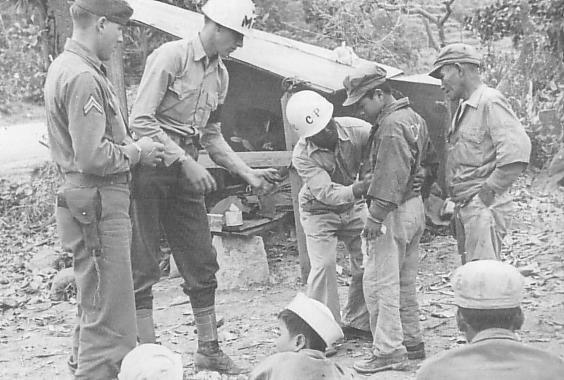

The history of Miyako jōfu textiles goes back four centuries. A man by the name of Shimoji Shinei, a yunchu1 administrator in the Sugama district office on Miyako Island, was onboard a boat which was about to sink. An excellent swimmer, he dove into the water and repaired the boat. As a reward, King Sho Ei promoted him to head of district. His wife Inaishi, wishing to express her gratitude to the king, wove and presented him an intricately designed ayasabi-fu in 1583, and thus Miyako jōfu was born. In 1610, the Ryukyu government levied a per capita fabric tribute tax system which led to an expansion of the production of Miyako jōfu.

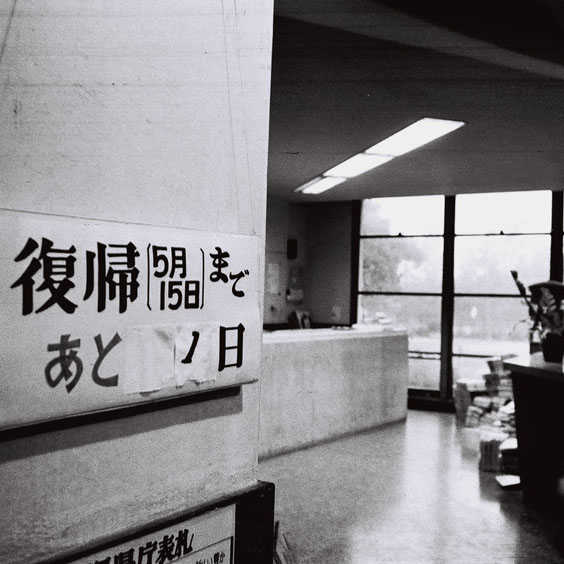

At its peak during the Taishō Period (1912-1926), Okinawa produced 17,000 bolts of Miyako jōfu annually, but by 1992, production had fallen to only three hundred2. (From Miyakojima City Traditional Crafts Center pamphlet and Okinawa Dentō Kōgei)

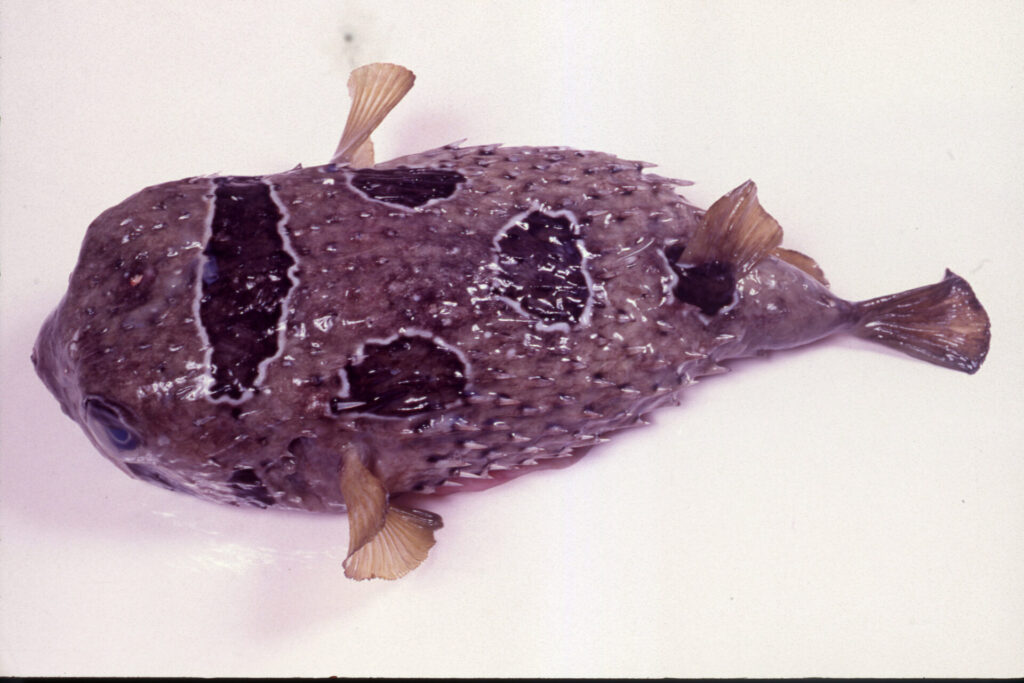

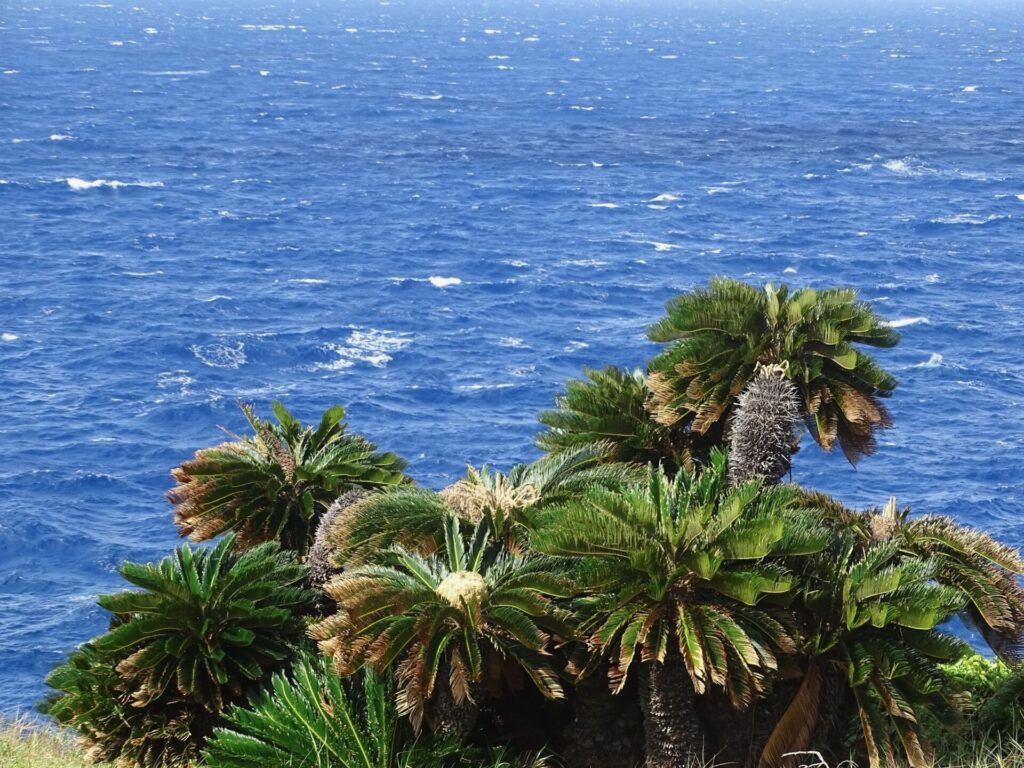

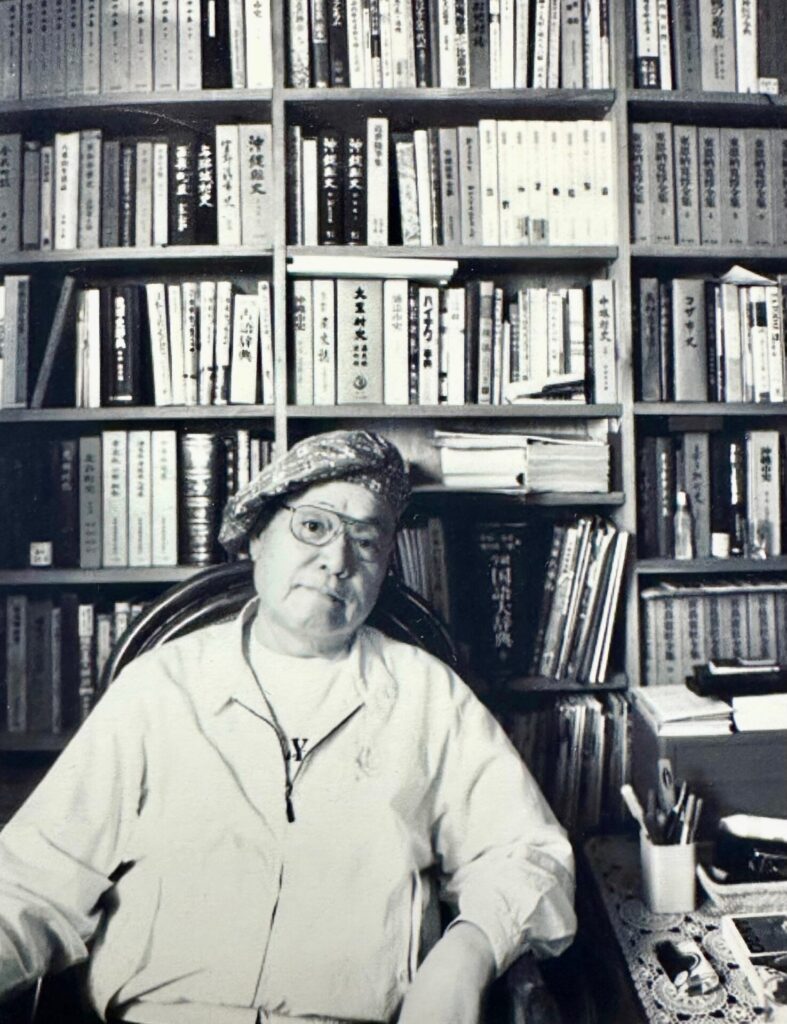

The process starts with peeling off the outer skin of the stalk of a ramie plant, which is in the nettle family. The stalks are then soaked in water until they soften and the fiber can be scraped up. Women then use their nails or fingertips to split the fiber into thin threads. The thread is so thin that it is barely visible to the naked eye, but the fibres must be separated in order to weave a thin, light cloth. One eighty-year-old woman, who has worked ramie since she was six, has now been recognized as a Master of Traditional Crafts by the Association for the Promotion of Traditional Craft Industries.

Women and children spin the fibres into raw bū, which is then dyed with Okinawan indigo and woven into intricate kasuri patterns.

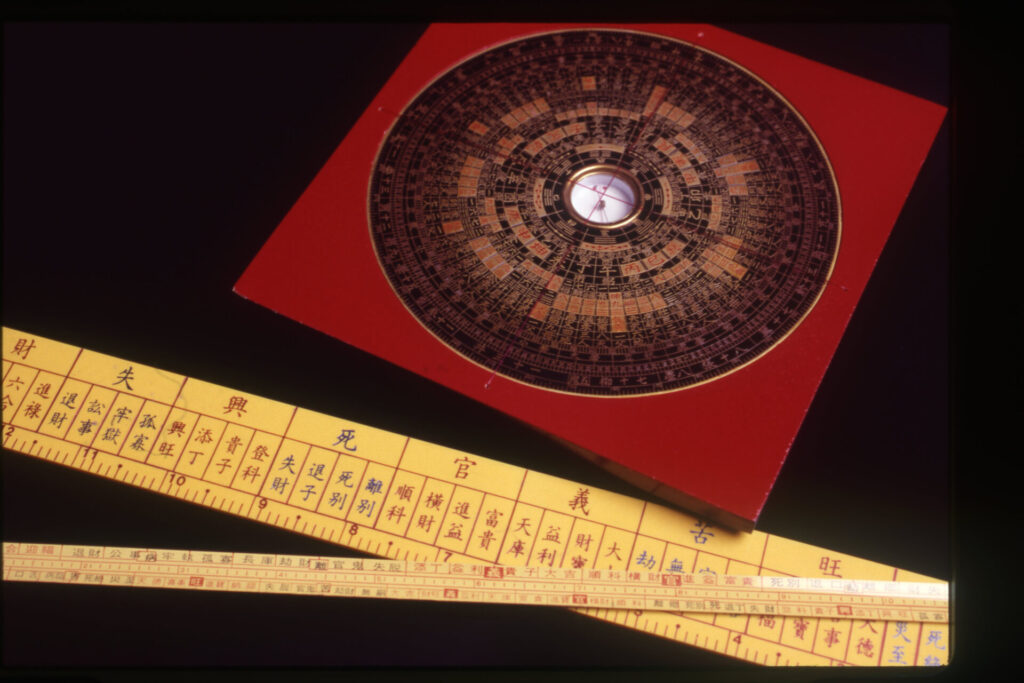

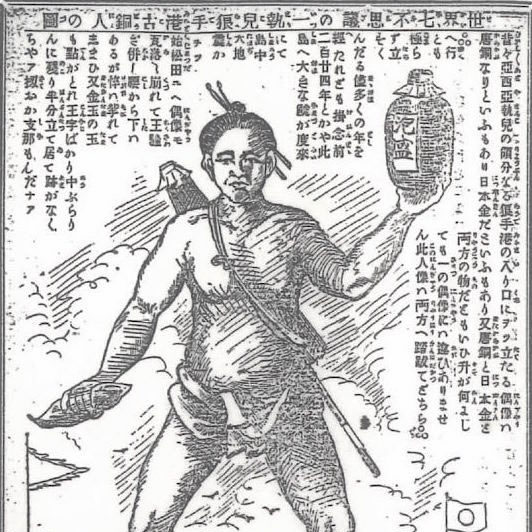

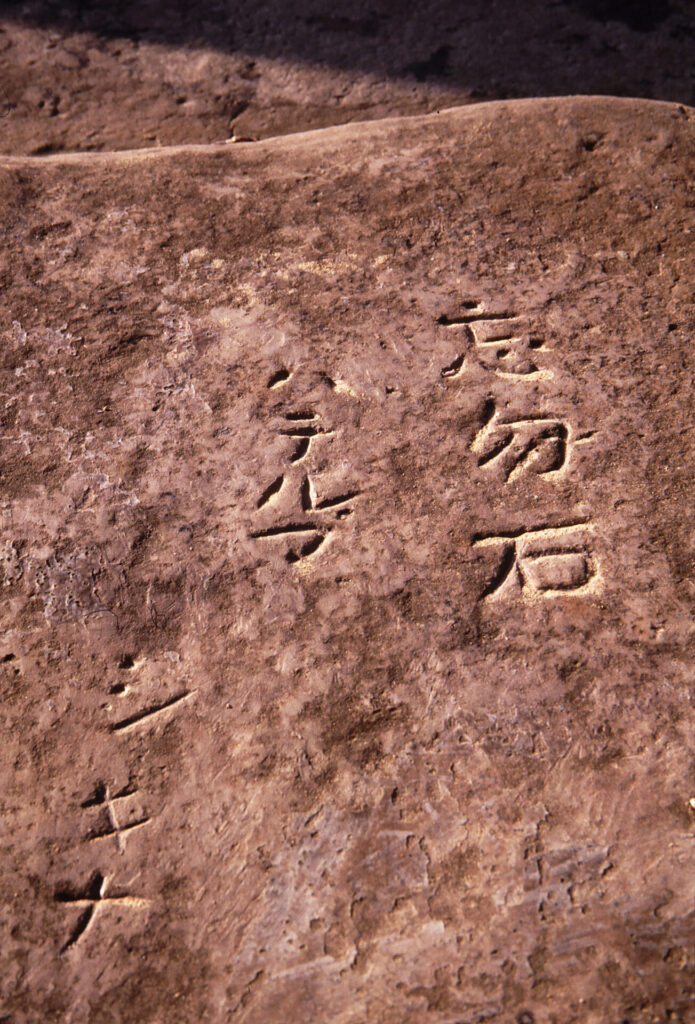

High-quality jōfu must foremost be thin. Okinawa is hot and humid, so residents prefer breathable fabrics. Bolts made for taxation were subject to strict quality controls: a standard bolt had to be so thin that, when rolled, it could pass through the hole of a copper sen3 coin. Anything that failed the test was classified as either middle- or low-grade fabric.

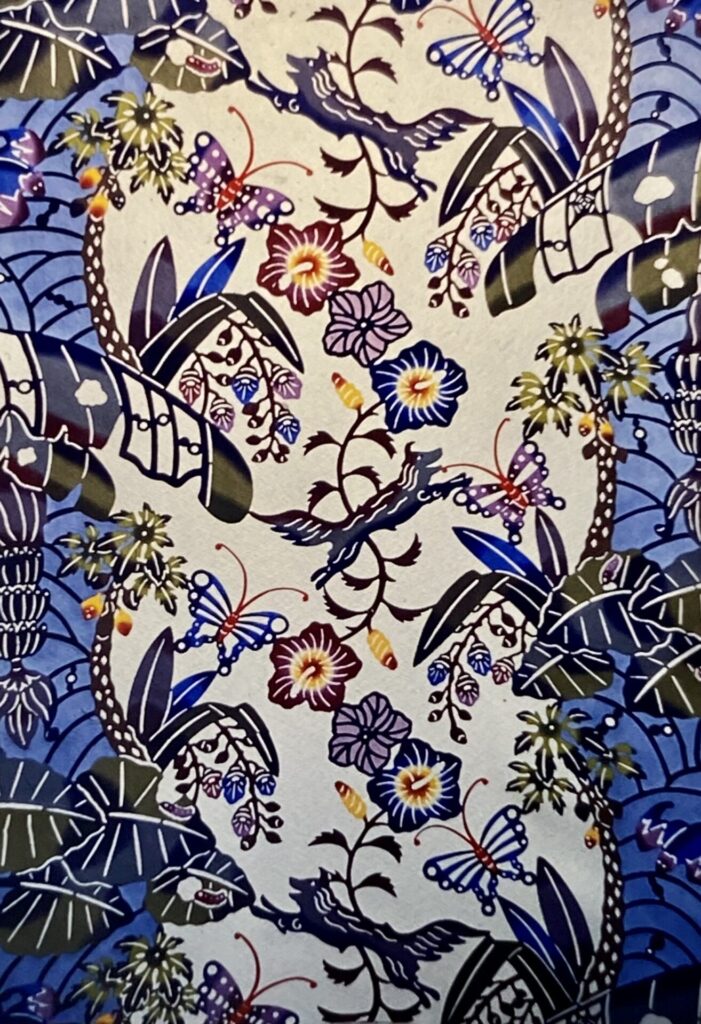

There were a few different patterns, but after Ryukyu came under Satsuma control and Satsuma in turn began presenting Miyako jōfu to the Tokugawa shogunate, new pattern requests were ordered from the Edo-based government. The records of these design requests serve also as proof of the ways the poverty-stricken people of Miyako were forced to weave away their own lives in service to a chain of exploitation.

Miyako jōfu is known for its intricate indigo kasuri patterns, but before Satsuma control, the people of Miyako also wove other brightly coloured jōfu. Recently since around the beginning of the 90s, young people have begun a movement to revive this art through organizations like the Adan no Kai. They produce colourful dyes using native plants like mangrove, bayberry, safflower, and fukugi, and dye and weave new patterns of their own design, a practice which stands in contrast to the traditional indigo jōfu.

Editor’s Note:

- An important officer in Miyako, Yaeyama Islands.

- In 2013, only six bolts were crafted (Ryukyu Shimpo, May 10, 2014).

- Ancient currency used in various countries around East Asia.